Construction Technique

Solderless Breadboards

We like to use these experimenter's tool also sometimes called a prototyping socket. They let us experiment with circut reconfigurations. Remember: They don't last forever. Keep your best circuts and start over with new sockets. You'll also need hookup wire.

We leave the first row of holes empty around each computer part so that we can program them in-place using a home-made BreadboardSpider connector.

Perfboard

Provides and easy way to assemble small projects in a more permanent way than provided by solderless sockets. Perfboard is expensive because of all the holes that must be drilled. The best product is made of fiberglass and has through-hole plated holes. Anything less means more tinkering to get a design to work. Buy one sheet and cut off small pieces as need be. See CuttingFiberglass.

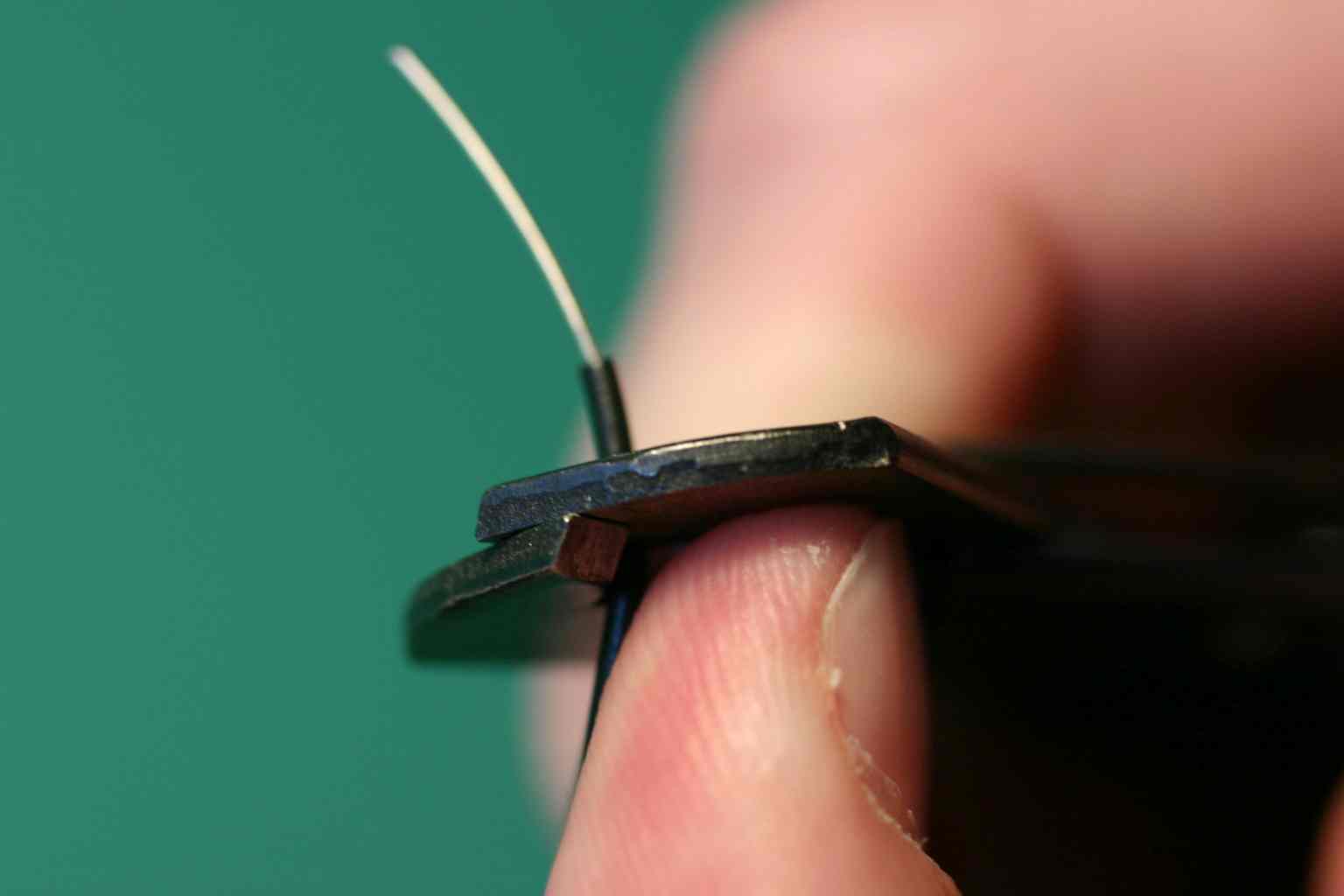

Hookup Wire

Use solid wire if it doesn't need to bend. Stranded wire will bend easily but doesn't plug into solderless breadboards easily. We use 22 gage wire. Some folks prefer 24 gage, which is smaller and goes in and out more easily. Get tined wire if you can. It takes up solder faster when you do solder it. Also it resists corrosion in the air, unlike bare copper, and this will keep your socket connections conducting better.

There is a knack to MakingJumperWires that are stripped on both ends.

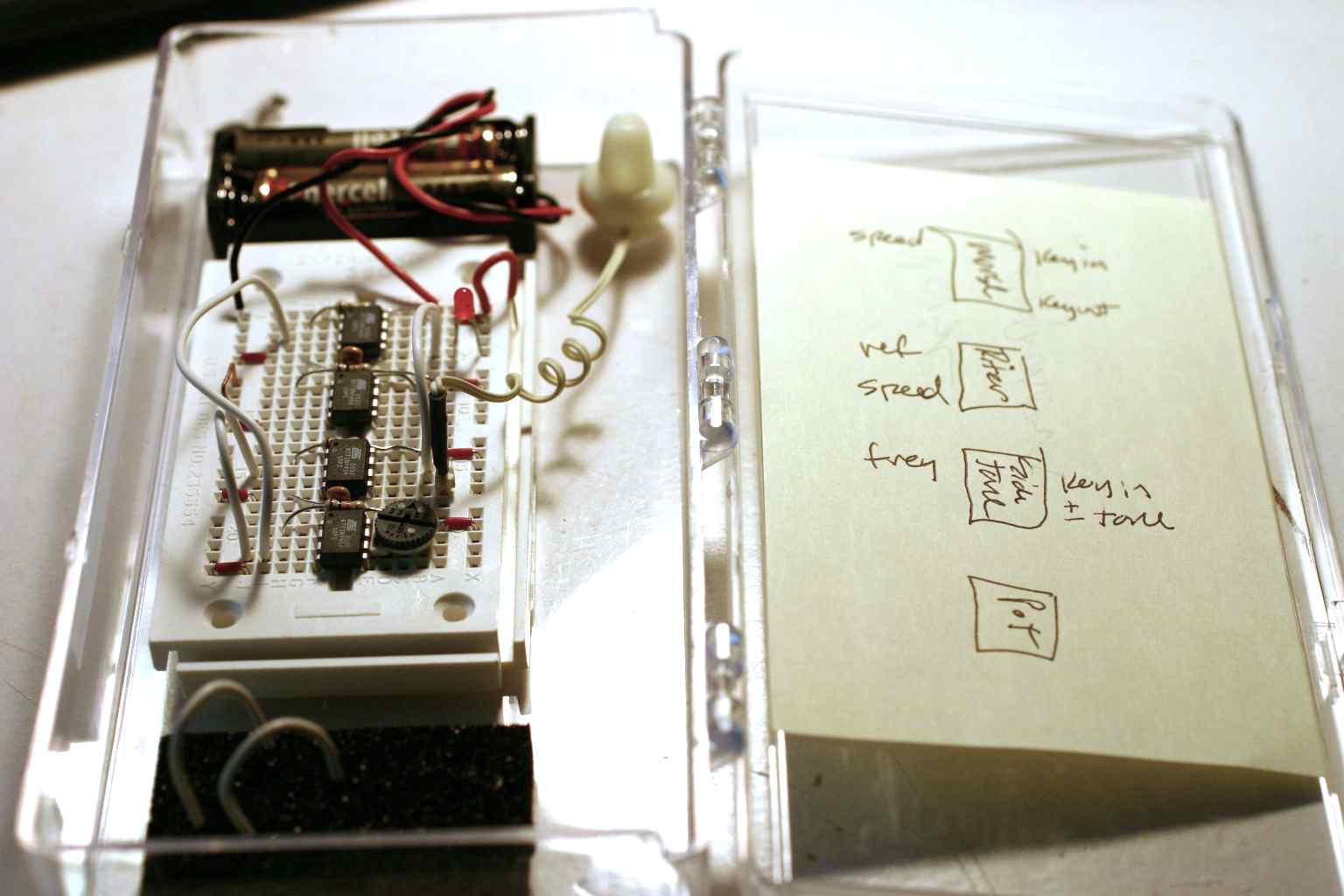

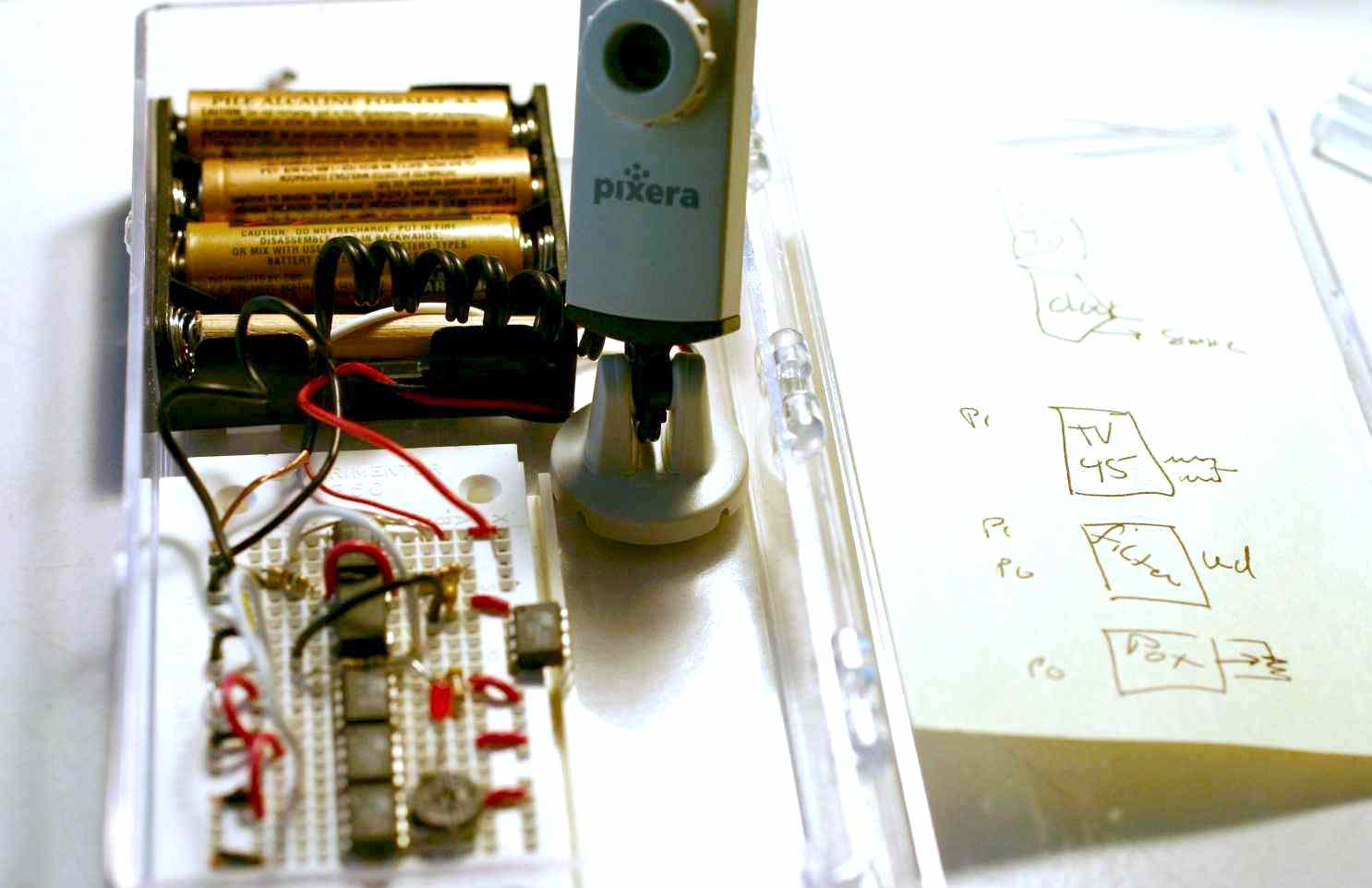

Project Boxes

I've started assembling them with battery packs in acrylic hobby boxes like those available from the Container Store. I use DoubleStickFoam to hold things in place.

I like to use a post-it note in the cover to remind me what computer programs I have loaded where. I write the name of the project on the back side of the note so that it shows through the lid of the box when closed. Consider throwing a thumb drive with all the source code in the box if you're going to set it aside for any length of time.

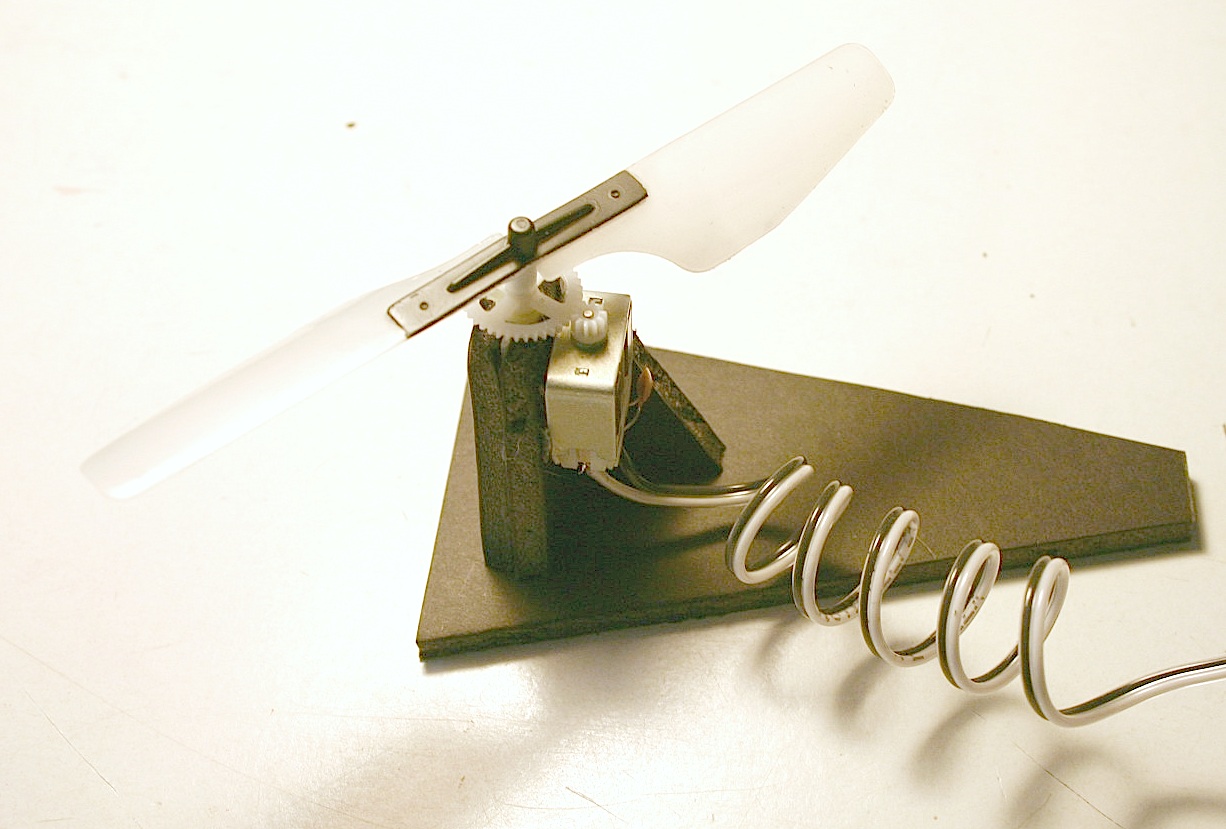

Foam Core Construction

This wonderful construction material is available from office supply and arts and crafts stores. I've seen it avalable in white, gray and black. It is about a quarter inch thick and easily cut with an xacto-knife. I use a steel ruler as a guide for straight cuts. Don't hesitate to build things with artful angles or even freehand shapes.

Here is a site that offers good advice for working with foam core. Number one tip: glue it with low temperature hot-melt glue. I've used double stick foam tape but will soon convert.

Return to WelcomeVisitors